Request

Requestinfo

Our excellence in the world

/Company

Aluminum surface treatments since 1964

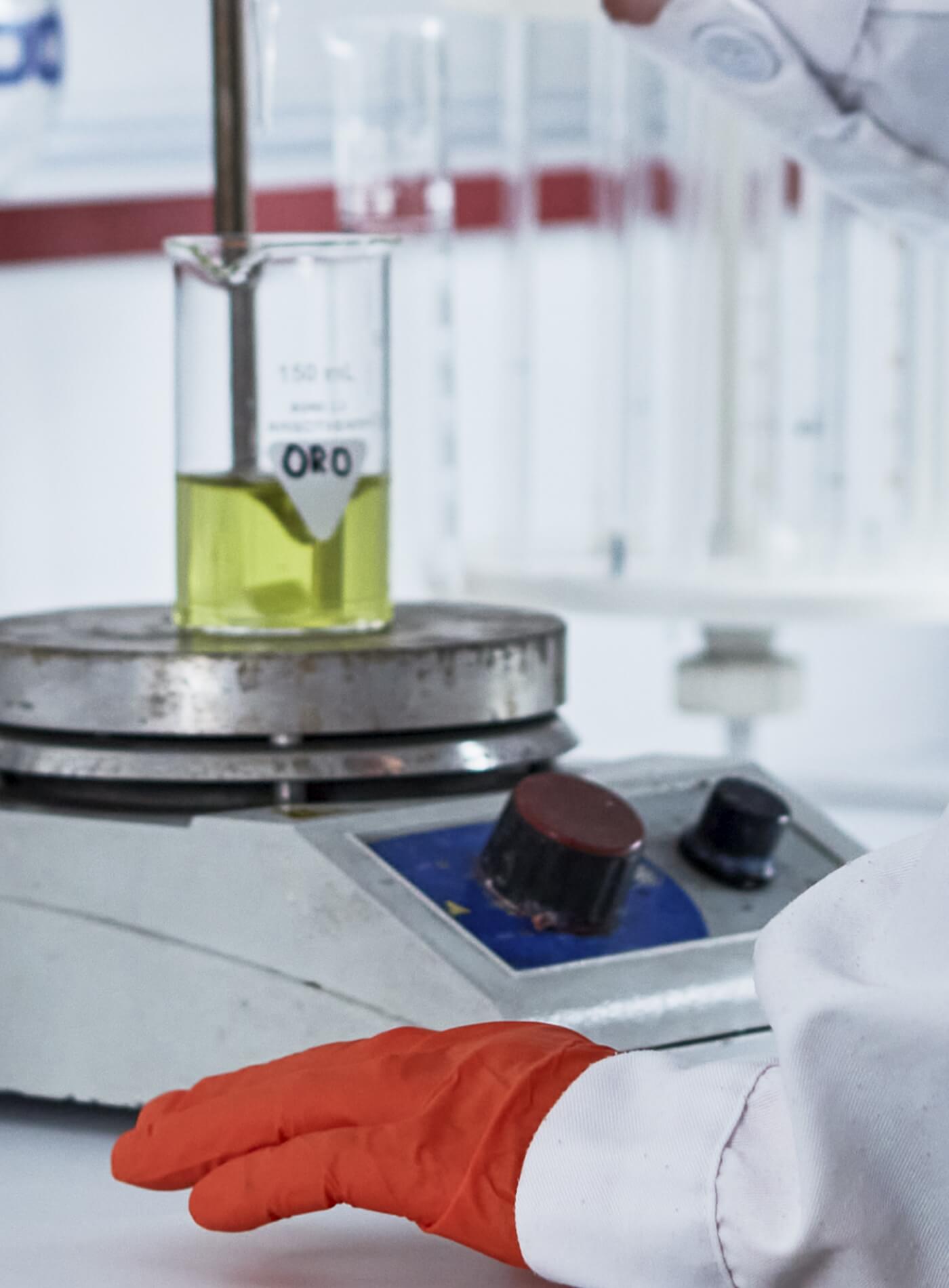

Oxidal Bagno is a historic aluminum surface treatment company, founded in 1964 by Gianfranco Bagno. Recognized today nationally and internationally, it stands out for its high production capacity, flexible services and wide variety of surface finishes.