Request

Requestinfo

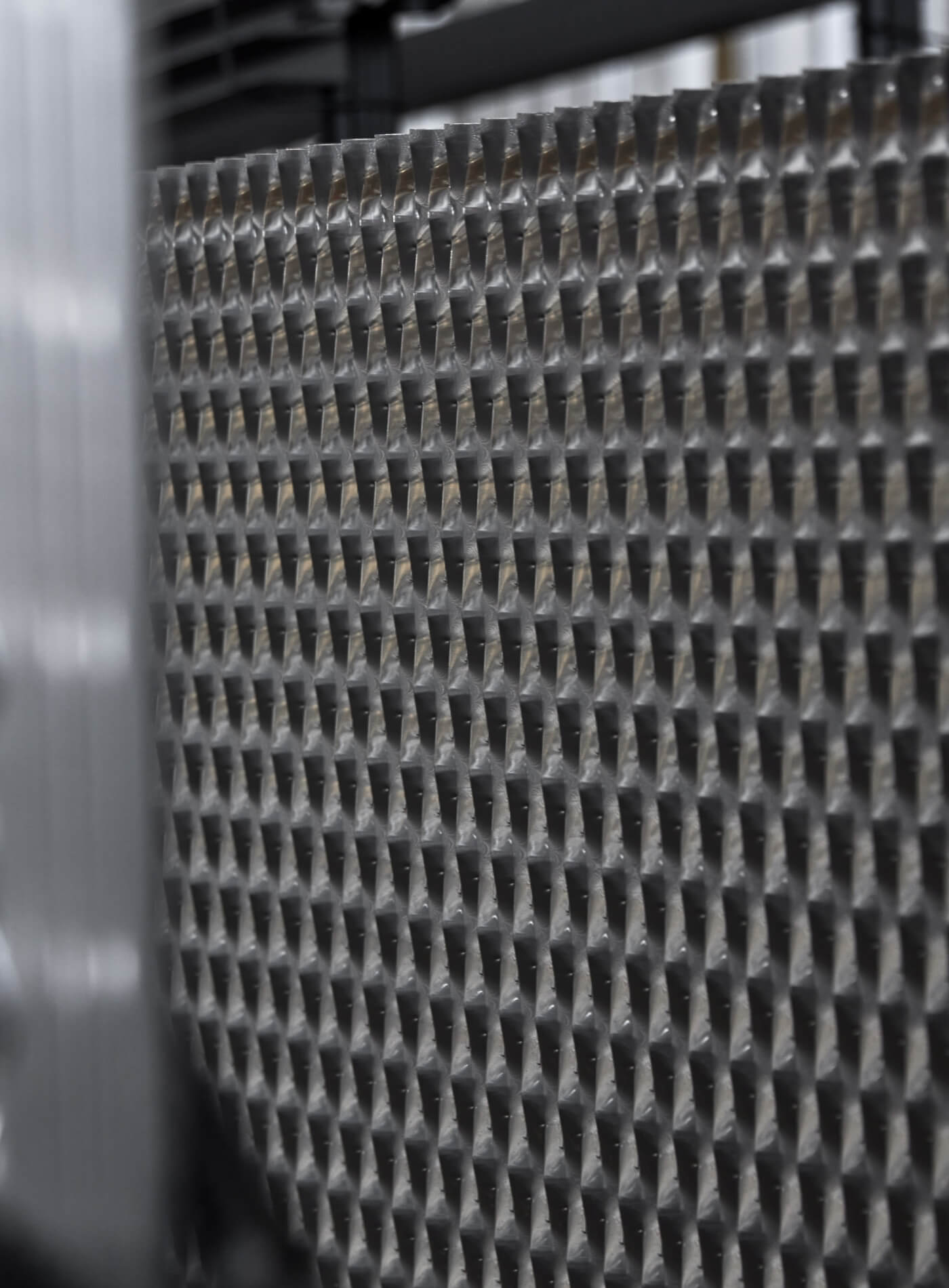

Quality comes through precision

Within Oxidal Bagno, qualified personnel are responsible for carrying out strict controls and precise checks at every stage of the production process, which are digitally recorded to enable orders to be tracked and anomalies to be alerted. All this in order to ensure the best service and the highest quality standards.

Precision and quality are at the heart of Oxidal Bagno: that is why controls are strict and carried out with the best instrumentation.

Production processes are carried out according to the highest quality standards, certified by the European QUALANOD Quality Mark, and approved according to BS (British Standard) and AAMA 611-14 (US) directives.

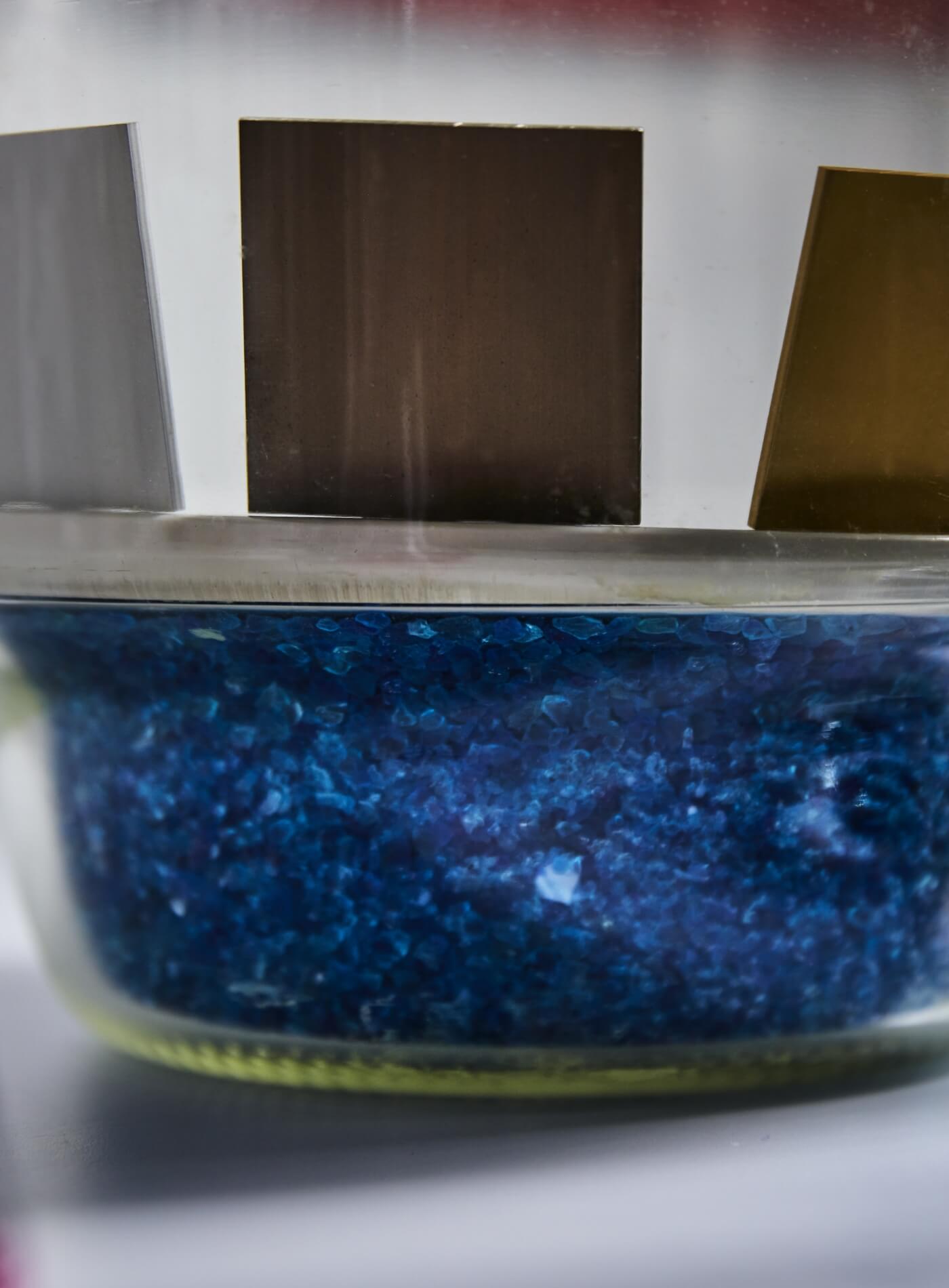

Pre-production checks, such as: verification of the performance of all material treatment stages, monitoring of operating parameters and feeding of working baths calibrated daily, according to actual consumption;

Production checks during processing: analyses of solution compositions are carried out as verification of correct working tenors;

Conformity testing of the finished material according to the destination and final use of the material. Depending on the morphology of the semi-finished products, the visible or hidden surface, the finish desired by the customer, the decorative and protective properties, and the chosen thickness class, post-production verifications are carried out.

An all-round quality control system,that ends with the testing of the finished piece to provide - upon request - a quality certificate for the individual job.

All in accordance with the requirements of the EURAS-EWAA-QUALANDO quality mark of which we are holders and in accordance with UNI 10681

Effective instrumentation and controls for proven quality.

Post production verifications consist of:

- Oxide thickness measurements with Isoscope [UNI EN ISO 2360]

- Fastener efficiency checks: mass loss analysis and drop test respectively [UNI EN ISO 3210] and [UNI EN ISO 2143]

- Evaluation of surface hardness: Clarke Test [BS 6161]

- Gloss measurement with Glossometer: Reflectance at 60°C [EN ISO 7668]

- Color measurement with Spectrophotometer; Colorimetry: EN ISO/CIE 11664-4 (ΔE) SCI method

- Visual inspection [EN ISO 7599]