Request

Requestinfo

Anodizing

/Anodizing

Anodizing

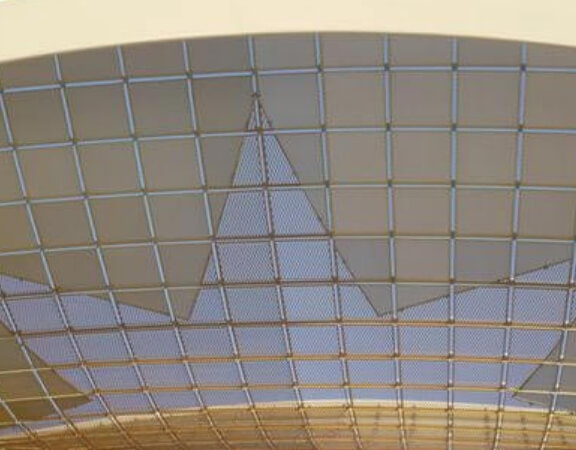

Aluminum anodizing is a process with a dual function, both anticorrosive and aesthetic, that converts electro-chemically the surface layer of the metal to oxide.

This layer can vary in thickness depending on the application: 5 to 10 microns for indoor applications; 15 to 20 microns for outdoor applications; and 20 to 25 microns for industrial and marine environments where weathering is particularly aggressive.

The process of anodizing aluminum has a dual function: anticorrosive and aesthetic

07/Gallery

×