Request

Requestinfo

Fixing

/Fixing

Fixing

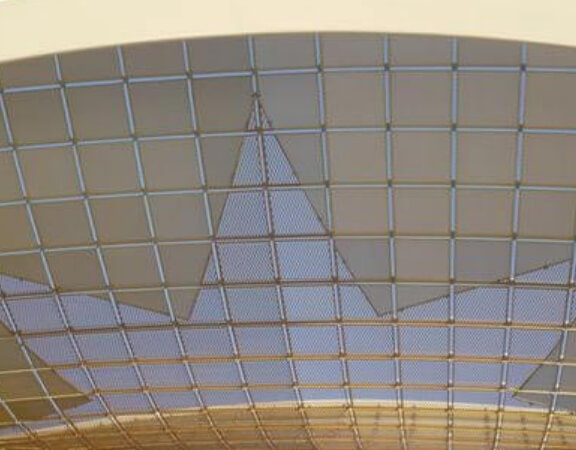

To maintain the anticorrosive properties and aesthetic characteristics achieved over time, aluminum materials subjected to anodizing require a final fixing treatment.

This process consists of closing the pores present in the oxide coating by two different techniques: hydration fixing, which is done hot, and impregnation fixing, which is done cold.

The aluminum is subjected to a final fixing treatment to maintain its anticorrosive properties and aesthetic characteristics over time.

07/Gallery

×